The surgical insertion of bone conduction implants is a complex procedure demanding extensive preoperative planning to get the positioning right. Simulation using 3D-printed skull bones may help optimize the process, according to a new study in Acta Otorhinolaryngolica Italian.

Researchers from Italy created 3D-printed models of temporal bones (the site in the skull for implantation of hearing devices) as well as a matching 3D-printed template to serve as a surgical guide. They used these models to select the most suitable place to embed the bone conduction implant.

The use of 3D printing technology to plan the positioning of hearing implants is feasible and a concrete alternative to current methods, lead author Dr. Pietro Canzi and colleagues from the University of Pavia wrote.

"The choice of the proper location of the device was much more intuitive and practical in comparison with radiological preoperative planning due to the employment of a three-dimensional model that is able to define all anatomical landmarks, regularity of the bone surface, and thickness of the underlying bone," they wrote.

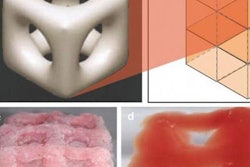

3D-printed temporal bones

Surgically installed bone conduction implants have risen in popularity due to the combination of improved hearing and reduced risk of adverse skin events they provide, according to the researchers. Correctly positioning the implant under the skin and onto the skull, however, relies on exacting dimensions and bone thickness as well as a sufficiently flat surface.

Presently, the placement of these hearing implants hinges on measurements drawn from 3D images of CT scans that offer a limited visualization of the skull, and accordingly, restricted preoperative planning.

"Identification of the proper location of the [bone implant], relying only on the radiological images, could be challenging because the best surgical positioning requires a three-dimensional study of the temporal bone considering its thickness, surface, and all anatomical landmarks," they wrote.

To ease and refine the procedure, the researchers turned to the binder-jetting technology of a 3D printer (Projet 460Plus, 3D Systems): They used the CT scans of three temporal bones to create 3D models of each one -- indicating bone thickness and including a representation of the sigmoid sinus pathway (Acta Otorhinolaryngol Ital, 31 October 2017).

In addition to making the 3D-printed temporal bones, the researchers used a different 3D printer (Form2, FormLabs) to fashion a transparent mask, or template, of the surface of the temporal bones based on the same previously acquired CT scans. By perfectly reproducing the anatomical landmarks of the temporal bone, the template ensured ideal positioning of the implant, according to the group.

"The template was developed to be univocally lodged on the specimen and allowing only one possible placement," they wrote.

Preoperative planning involved aligning the 3D-printed template on top of the 3D-printed temporal bone, marking the designated site for the bone implant using a marking tool known as a transducer-sizer, and drilling corresponding holes with a drill press.

Optimal placement

Setting the drilled 3D-printed template on the human temporal bone guided all three surgical implantations of the hearing device. The procedure took 21 minutes on average and prompted no difficulties in implant positioning.

The mean difference between the implantation sites on the 3D-printed model and the human temporal bone was 0.13 mm, as verified on subsequent CT scans.

| Distance between anatomical landmark and bone implantation site on temporal bone | ||

| Surgery | Human temporal bone | 3D-printed temporal bone |

| 1 | 46.51 mm | 46.84 mm |

| 2 | 43.41 mm | 43.51 mm |

| 3 | 58.66 mm | 58.66 mm |

The short surgical time and minimal differences in the positioning of the hearing device are advantages of using 3D printing to prepare for bone implantation, according to the researchers.

"In all three cases, quick identification of the appropriate [bone implant] position was accomplished," they wrote. "The transparent template enabled safe identification of the planned [bone implant] position on the temporal bone, previously localized on the 3D-printed model."

The authors noted a need to decrease the size of the 3D-printed template as well as modify their approach to make it more appropriate for a clinical setting. These adjustments would allow them to evaluate the clinical applicability of this technique in future studies.

"A minimally invasive approach considering soft-tissue management represents a key point that should be clarified for the application of our 3D printing guided method on the patient," they wrote.